Derksen Co. Creates Recyclable Label and Custom Label Applicator for Coffee Company

Cambio Coffee Roasters Sustainable Labels and Label Application Equipment

Today, we’re taking a special look at a new Derksen Co. project that has been in the works for a recyclable coffee pod brand called, Cambio Coffee Roasters. This creation is a special one. Not only did the labels need to be stylish and able to facilitate easy recyclability, but the application process needed to suit an irregular container, meaning the applicator as well as the labels needed to be custom made. We always talk about the “Derksen Difference” and our willingness to create innovative and tailor-made solutions when it comes to labeling. As we say: if you can dream it, we can print it. And that is exactly what happened with Cambio Coffee. They came to us with a creative packaging idea and we brought their vision to life.

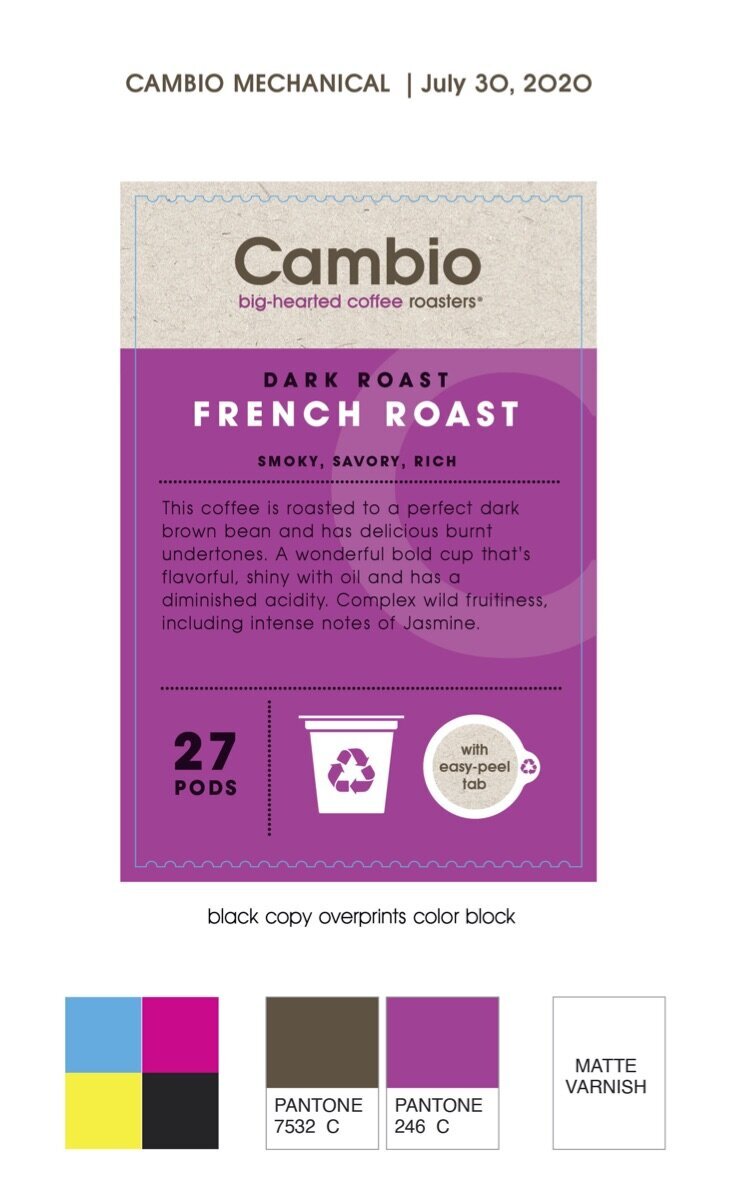

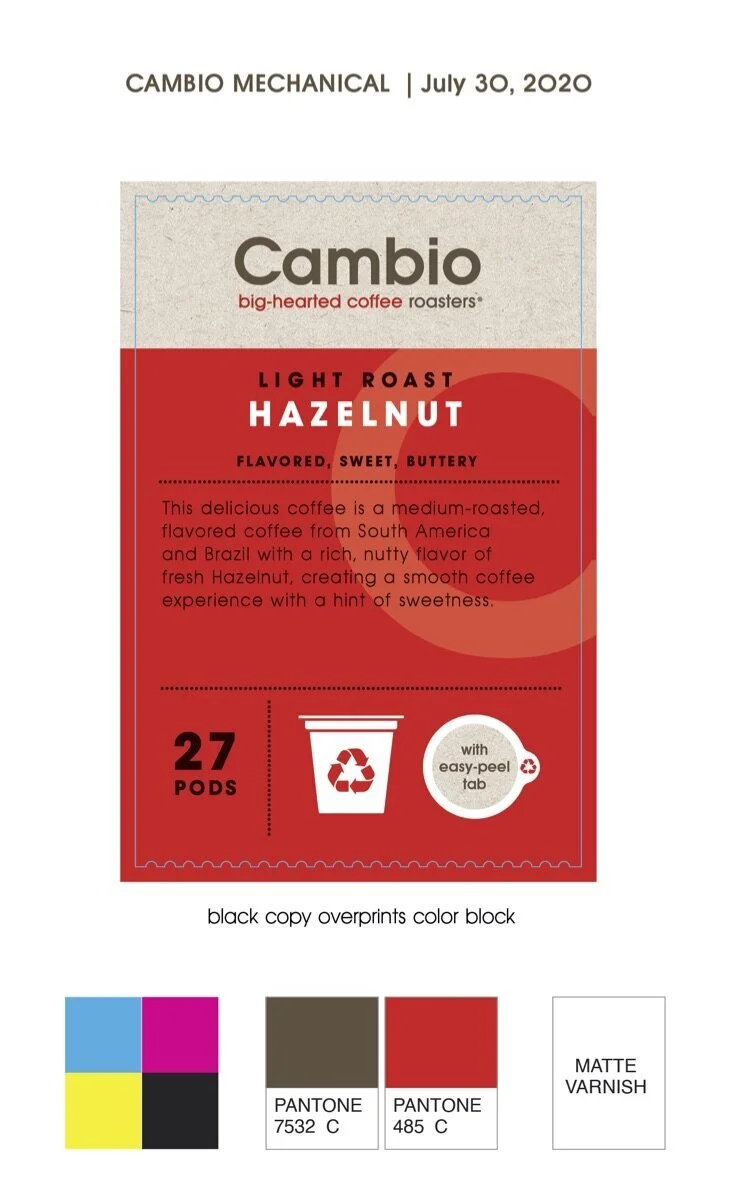

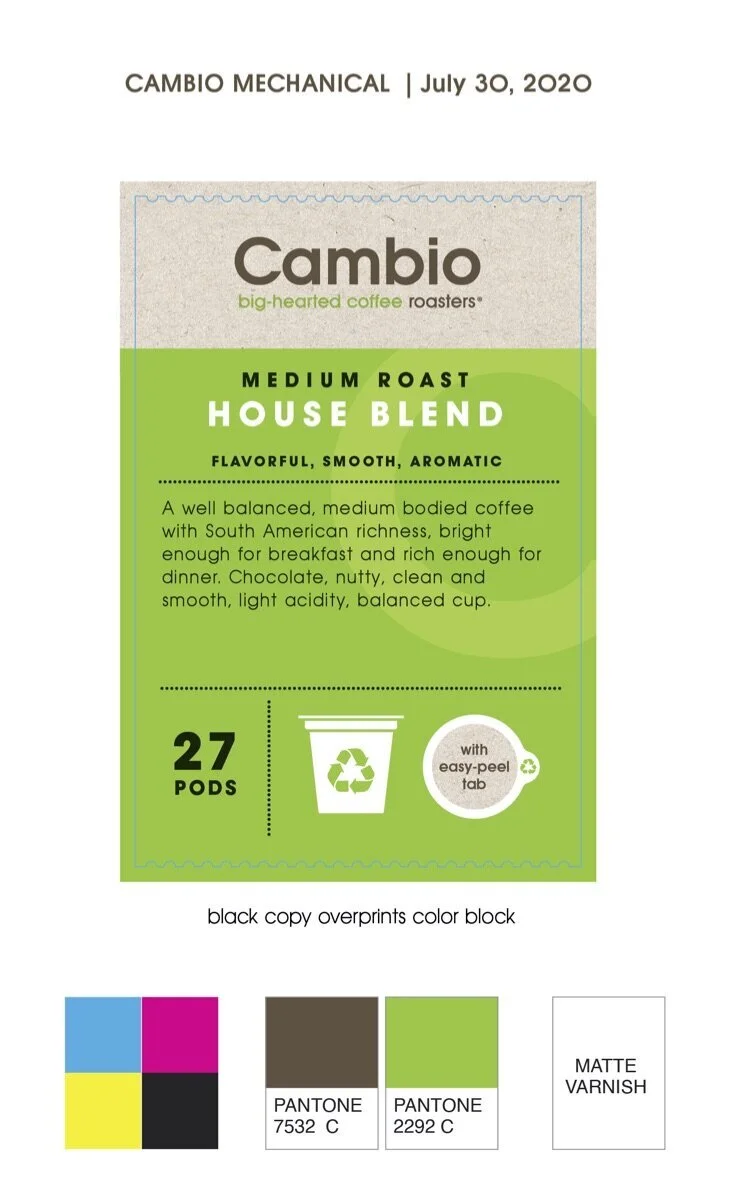

Part One: The Design

Cambio Coffee Roasters Custom Designed Flexographic Labels

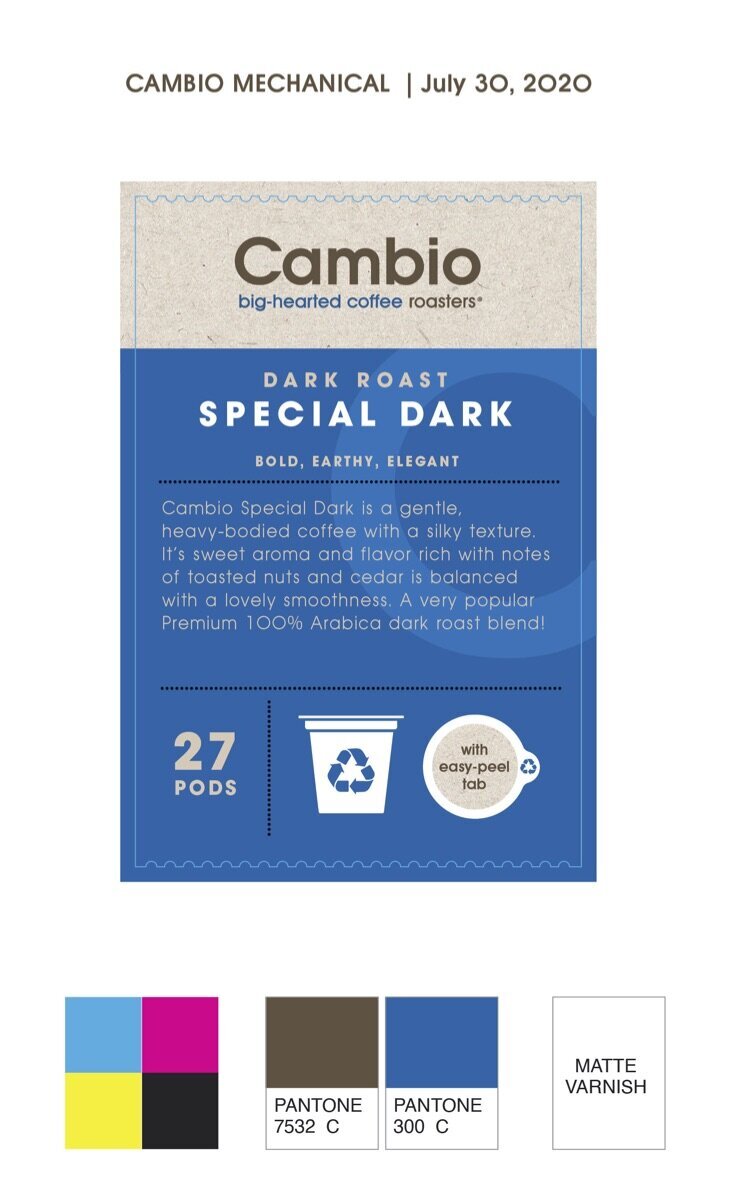

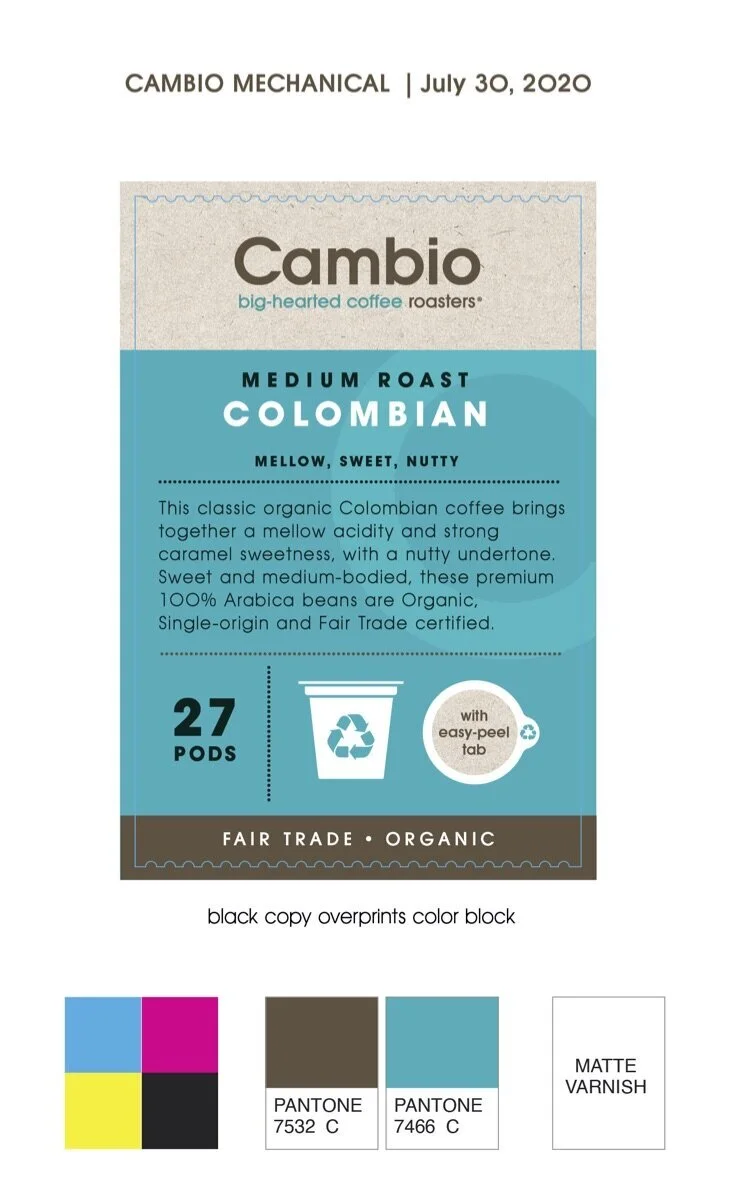

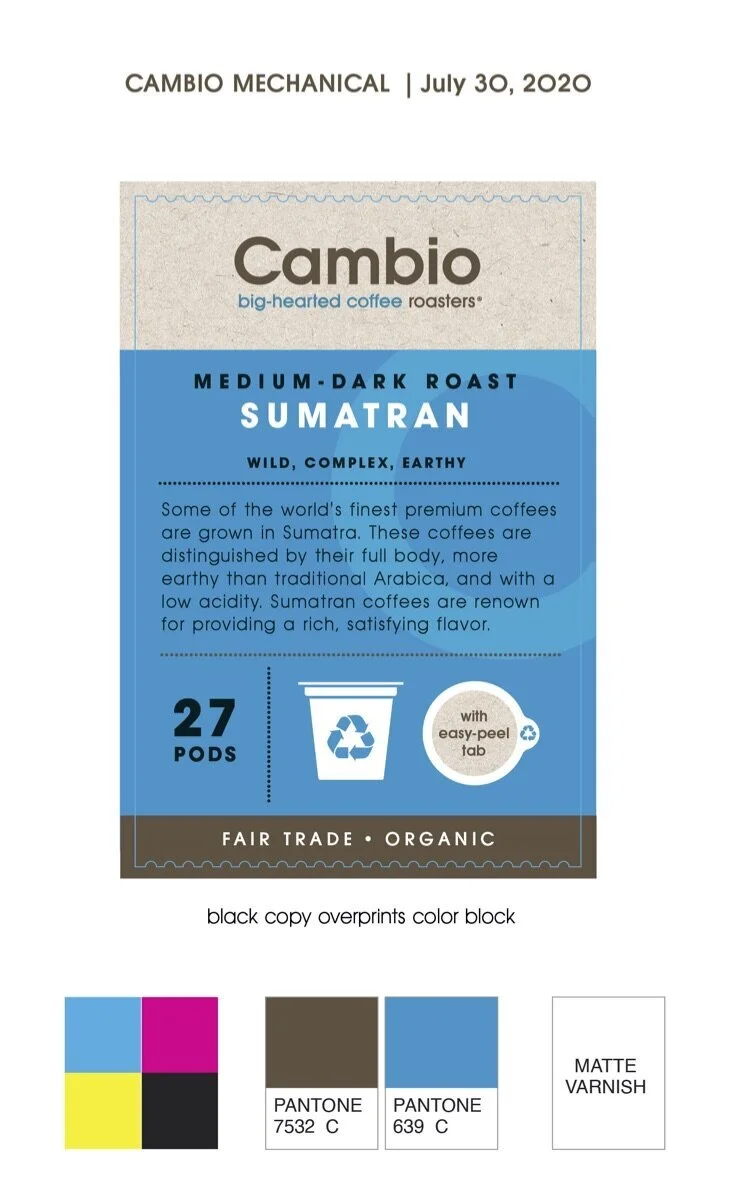

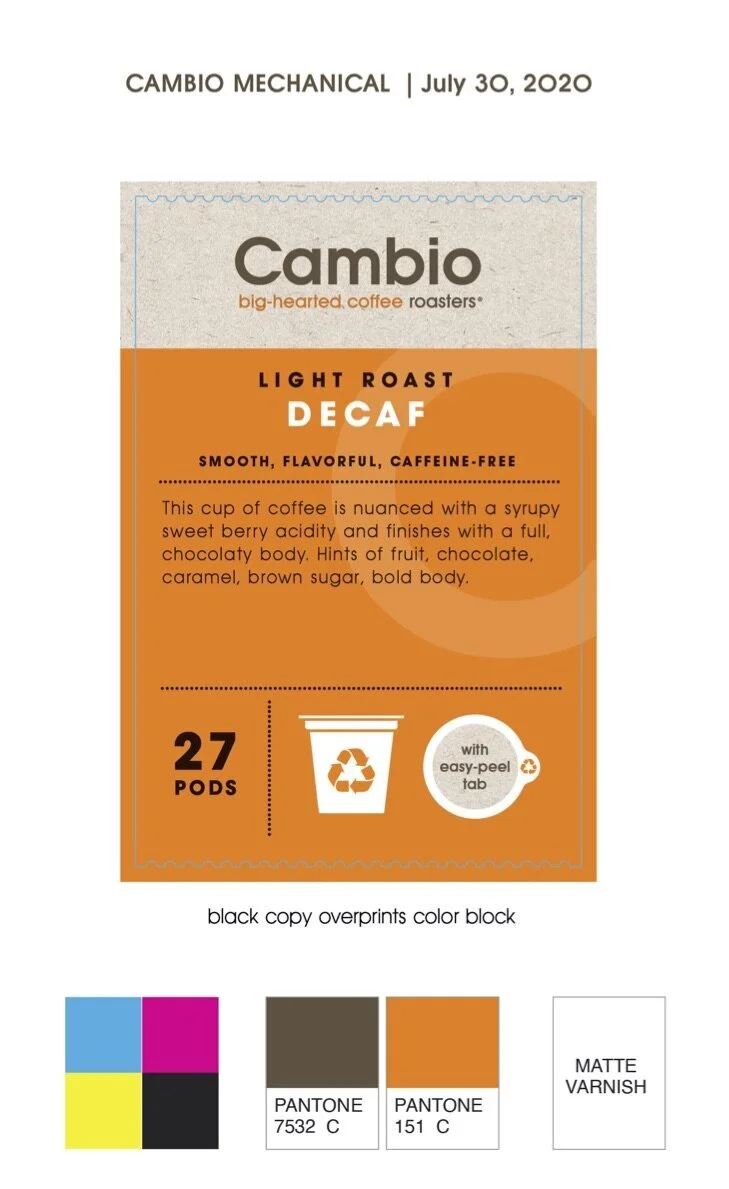

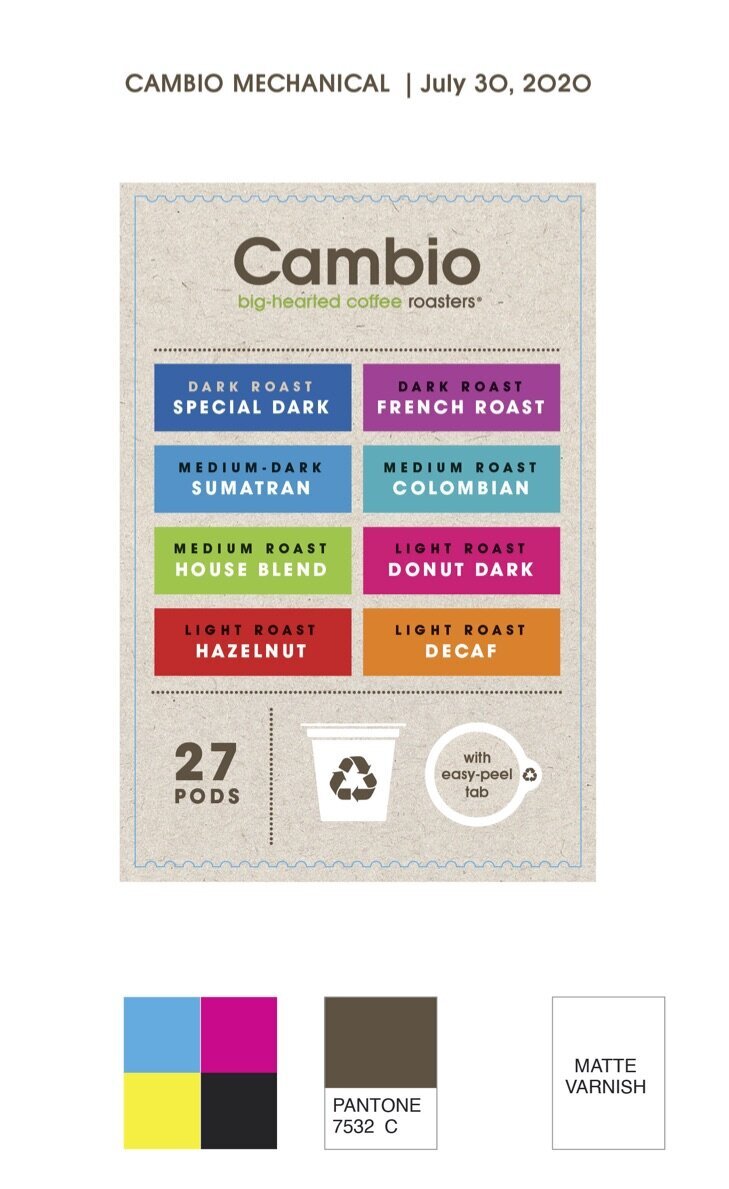

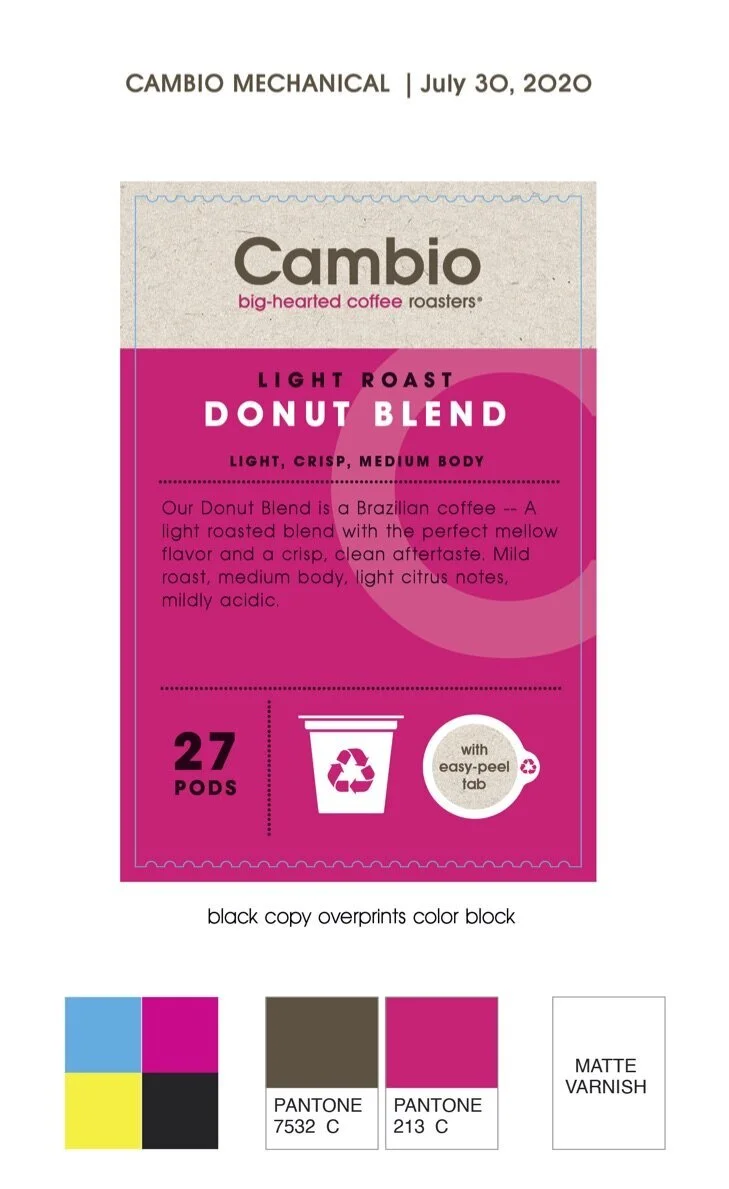

Cambio Coffee Roasters already had a well-established style to their packaging. Bright colors and bold text adorned their coffee pod boxes and we maintained the integrity of their original conception. Derksen Co, created a series of label designs to suit Cambio Coffee Roasters’ eight roast varieties and compiled a ninth piece of artwork suitable for a variety pack of coffee pods. Designed for flexographic printing, each label houses detailed textual elements and crisp shapes. These will be finished with a matte varnish, giving their exterior a sleek and clean look.

Part Two: The Label

Cambio Coffee Roasters Recyclable Label

Cambio Coffee is dedicated to sustainability. So, their label had to comply with their mission of creating great coffee while reducing waste. Taking their original designs and fusing them with a label that could facilitate easy recycling, Derksen Co. established a series of labeling options that can suit their wide variety of coffee products as well as the brand’s environmentally-minded goals.

The Cambio Roasters labels are printed in 2 or 3 color and are printed with a perforated edge on High Density Polyethylene (HDPE) film, which is an easily recyclable plastic making the labeling process much greener than if adhered to other film types. The problem with recycling most labels is the label adhesive. Widely used adhesives don’t always separate from the label substrate, which creates problems in the recycling process as the adhesive will contaminate the recycling pulp. To get around this issue, the Cambio labels are printed with a water-based adhesive which separates from the substrate at the recycler. This essentially means that the label and the adhesive cleanly separate so that the recycling process isn’t hindered. So basically, the label – including adhesive – used in this construction facilitates recyclability as opposed to hindering it, making sure that Cambio can fuse its packaging with its goals for sustainability.

Part Three: The Applicator

Custom Label Application Device

Once the label design was finalized, we needed to make sure that the label application could suit the product container. Cambio Coffee Roasters feature a trapezoid-shaped container in which they ship their coffee pods. Because the container shape is slightly irregular, Cambio needed a custom-fitted solution for their applicator. We sought out Take-A-Label for this custom applicator project and came up with a solution to make sure that the label was adhered smoothly and soundly each time. After playing around with a few options, we settled on attaching a jig fixture to a tamp applicator that could suit the container’s gradient.

The jig fixture is placed at the base of the tamp applicator. Tamp applicators work by pressing down on the product surface with the label to adhere it. Constructed with a mechanical arm and a pad at the end, this type of applicator works by pushing the pad down onto the product surface to apply a pressure-sensitive label in a fixed position. The mechanical arm is situated at a flat angle, so for irregular-shaped containers, such as with Cambio, the tamp needs to be adjusted so that when the tamp comes down onto the product with the label affixed to it, the label hits the surface with even pressure. In order to accomplish this, a jig fixture can be added to raise the product container at certain angles, therefore allowing it to accommodate the tamp’s range of motion. Cambio’s jig-fitted tamp applicator applies even pressure to the Cambio container, firmly affixing their custom recyclable label to their product.

This project was one for the books! You can find out more about our custom labeling solutions by contacting our team at Derksen Co or by giving us a call at 920-685-4000!