Pre-Printed Product Labels and Thermal Printing

HOW TO START YOUR OWN LABEL PRODUCTION

When it comes to businesses that have an extensive product line, like bakeries or cheese shops, often the most cost-effective solution for product labeling is to produce labels in-house. With thermal printing, companies can imprint data on a branded label stock. This means purchasing only one label. This flexible and efficient approach to labeling is appropriate for a variety of industries and can suit a wide range of packaging needs. Find out how to start your own label production with Derksen Co.

DIGITAL OR FLEXOGRAPHIC PRINTED LABEL STOCK

Alongside our team, you’ll help to create a pre-printed label stock design that reflects your brand’s identity. Whether you want to go minimalistic or incorporate intricate graphics, our team can help bring your vision to life. Depending upon your product labeling needs, we can create a label that has room to imprint any data you may need to incorporate on the final product.

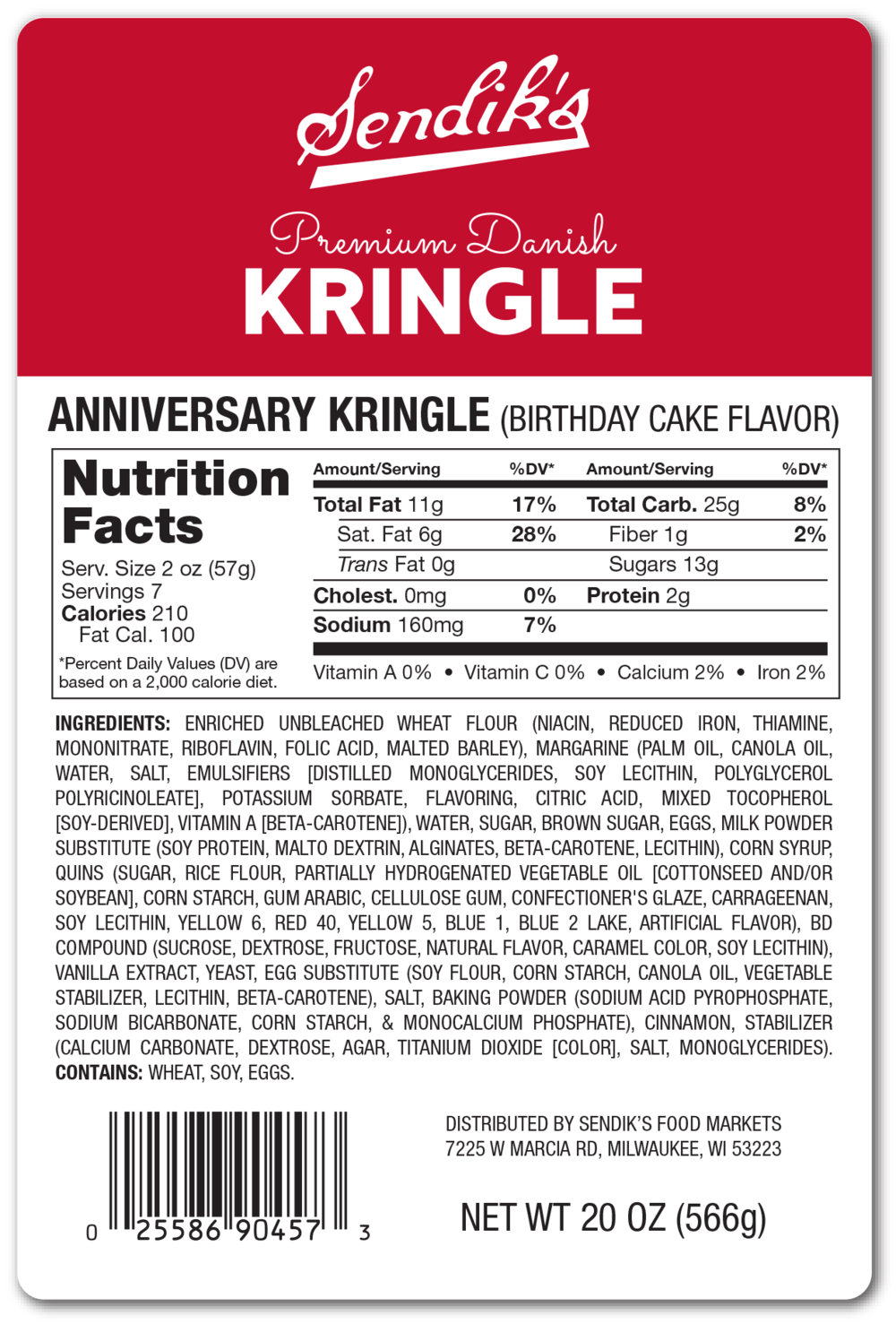

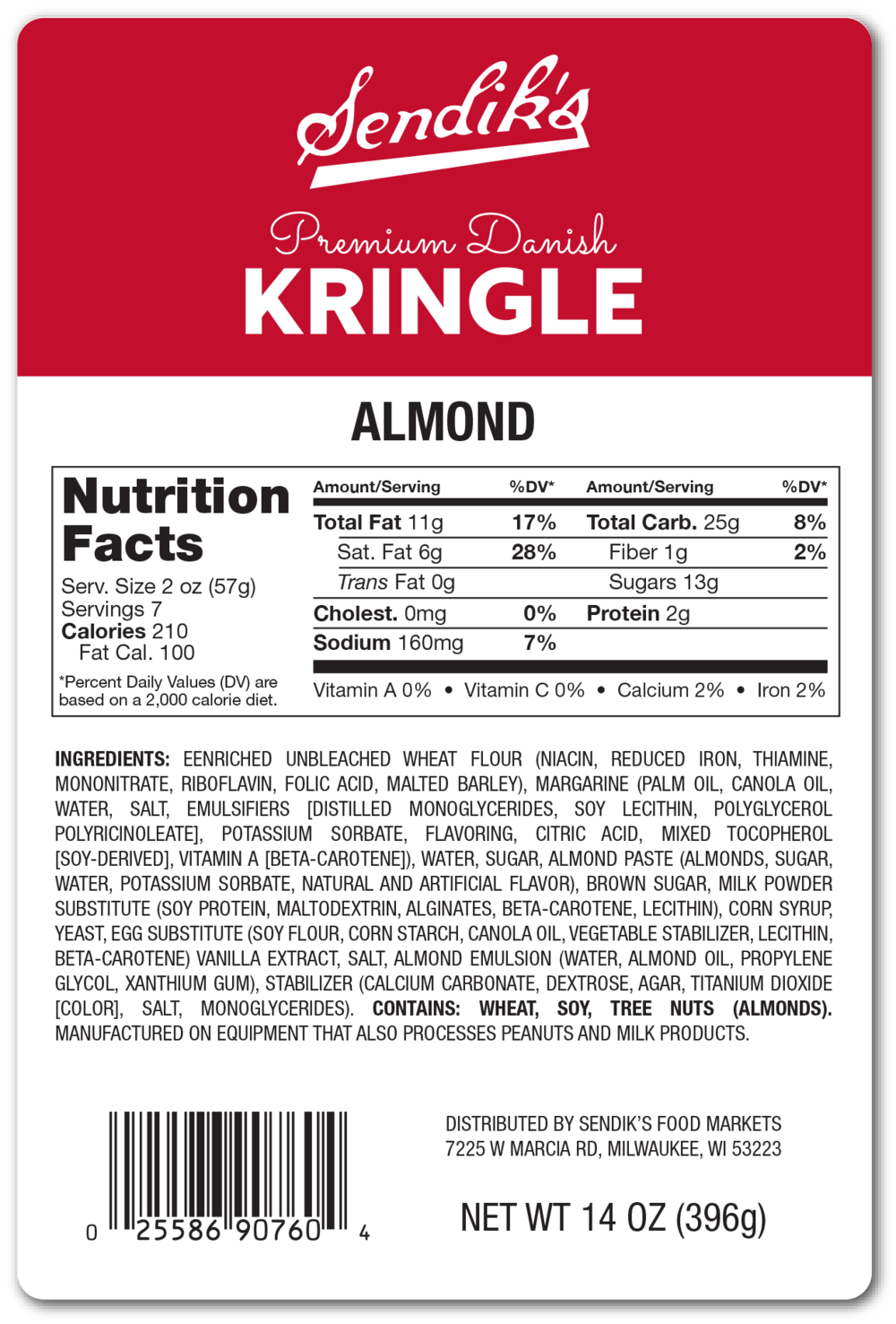

These Sendick’s Kringle labels, pictured above, employ flexographic printing and 600 DPI (Dots Per Inches) thermal transfer printing. Using NiceLabel labeling software, the nutrition information, title, graphics, bar code identification, and ingredient list are printed onto the branded label with a ribbon.

ON-DEMAND LABELING

Thermal transfer printing is on-demand, which means that when you need labels, you can simply print them yourself. Thermal printers are sized by their Dots Per Inches density. Typically, they range in resolution from 200 DPI to 300 DPI, all the way up to 600 DPI. The DPI determines the quality of the printing capabilities, so depending upon your printing needs and your preferences, you may choose one of the three thermal printing resolutions for your operations.

To learn more about how to start your own label production and how thermal printing could be integrated into your product production, contact our team at Derksen Co. Be sure to sign up for our newsletter to keep up with our blog and news.