Wine Packaging Changes and Design Updates

Wine Label Printing Techniques, Trends and Emerging Technologies

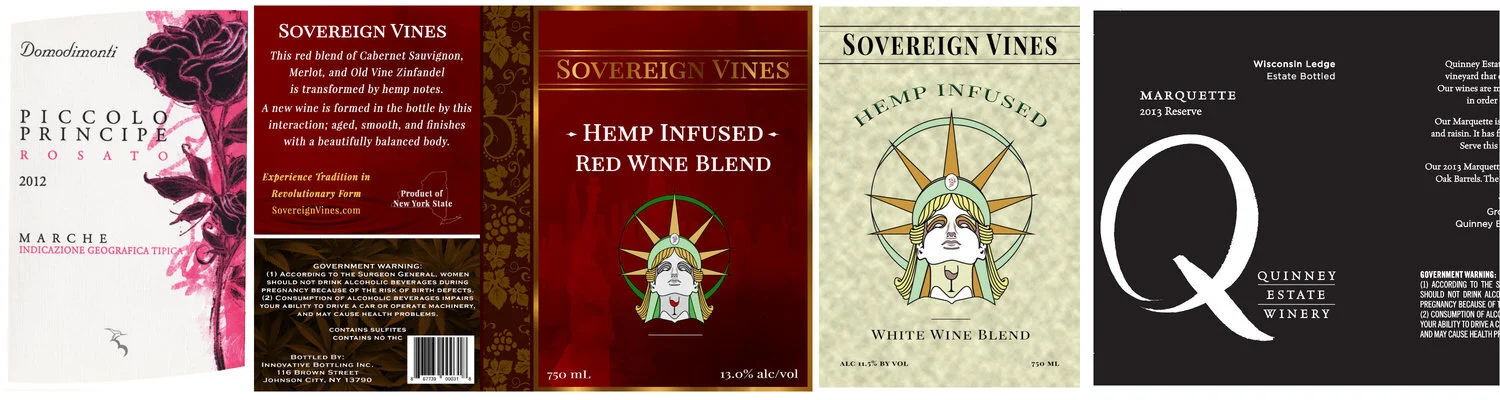

Some consumers, or connoisseurs rather, know the grape variety, location, and harvest year of their favorite wines. But, for those shoppers who have a more casual relationship with their wine, packaging can make a great deal of difference when it comes to what stays on the shelf and what makes its way to a consumer’s home. Majority of shoppers are concerned with few criteria and are presented with an innumerable amount of options when it comes time to purchase. It is for this reason that the wine packaging and wine label industries are so robust, diverse, and often, where the most creative approaches to printing techniques and packaging technologies can be found.

PAPER STOCK AND LABEL MATERIAL

Though it may seem simplistic, changing the stock on which a label is printed can change the entire integrity of the label design and enhance the look and feel of the label itself. Stock materials span a diverse range of options that can help to intensify the look of printed colors, create textures and mimic natural materials like wood, fabric, and even substances like velvet. Hundreds of different colors, thicknesses, and textures offer an enormous degree of customization and potential.

EMBOSSING AND DEBOSSING

Embossing and debossing techniques can create relief text and graphics on wine labels and help to emphasize certain elements of the label design. Created through the use of plates and machinery, embossing is commonly combined with metallic foils to create an even more dramatic impression on the eye of the consumer. Similar in process, debossing can be used to create a variety of textures and to accentuate lettering and graphics on the label. Both techniques help to differentiate certain elements in the artwork and create rich designs when combined with premium printing stock.

VARNISH OPTIONS

Though varnish can be applied as an all-over finish on a label, it can also be employed on certain parts of the label to create texture, accentuate certain elements of the label artwork, and add a degree of luxury to the look and feel of the label. Varnish can add depth and even be layered to create a tactile effect. Such relief varnishes can add high-gloss detailing to labels and create a pleasing sensory experience for customers. Varnish can even go so far as to create braille on labels and can be used in a number of creative applications.

DIE-CUTTING POSSIBILITIES

In recent years, the application of die cutting has expanded the possibilities for label production. Especially in the wine industry, die cutting techniques have created new and unique ways for brands to present their products. Internal die cutting can be used to create relief lettering and relief graphics, and exterior die cutting can be used to create a unique shape that defies the traditional square and rectangular wine bottle label appearance.

LABEL APPLICATION STYLES AND LAYERING

Increasingly, to create greater depth and texture, wine producers are choosing to layer labels for a more pronounced effect. This technique circumvents difficulties associated with heavy stock usage and creates a greater sense of depth when applied to the bottle.

SPECIAL TECHNOLOGIES

Special technologies and printing techniques that have gained popularity in the wine packaging industry include a variety of options that increase individuality in branding and can create striking imagery. Lenticular label designs work to achieve three-dimensional effects. Two images are spliced in alternating columns and then a plastic corrugated layer is placed on the top of the label to direct the viewer's eye to either the left or right frames. The result is a shift between two images that helps to engage consumers and create added interest on the bottle. Other techniques that are growing in popularity include double-sided labels. This printing technique can be especially useful when printing labels for white or rose wines as the bottle and contents are transparent and allow for the visual intricacy of double-sided labels to be used. The use of thermochromic inks, while rare in the wine industry, has interesting potential. Like a mood ring, these inks change color depending upon the temperature and can be used to make the label change color with the consumer’s touch, or on a more practical note, to indicate that a wine is sufficiently chilled to the proper temperature for drinking.

FOILS

While foil applications have been present in the wine label industry for quite some time, recent developments in printing capabilities have enhanced the possibilities and applications of foils to create new and exciting opportunities to enhance label design and bottle artwork. Cold or hot stamped foils are an easy way to add interest to a label and to create a high-quality look.

SHRINK WRAPPED WINE BOTTLES AND SHRINK-PAPER SLEEVES

Shrink wrap sleeves allow for a 360-degree artwork to be applied to the wine bottle. Though non-conventional, shrink wrap is growing in popularity in the wine label packaging industry. This technique has a multitude of possibilities when it comes to design and is striking when placed next to traditionally labeled bottles. A variety of interesting printing options can be employed when choosing shrink wrap sleeves including glow in the dark ink, matte and gloss finishes, metallic details, textured details, and intense colors. Shrink-paper sleeves are similar to shrink wrap, but have a paper texture with an adhesive underneath. Like their plastic counterpart, shrink-paper sleeves can combine numerous printing techniques, but retain a more stylized texture and density than plastic.

DIGITAL AND FLEXOGRAPHIC PRINTING IN WISCONSIN

Derksen is a full-service commercial printing company, which specializes in custom label creation and packaging design. For further information about wine bottle labels, wine packaging techniques, and packaging possibilities, contact the Derksen team at 920-685-4000.