What is Die Cutting and How Does it Work?

DIE CUT LABELS IN PACKAGING

In label design, much focus is placed on artwork, inks, overlays, and varnishes but an overlooked player in labeling is the die cutter. This sometimes underused tool can produce truly fantastic effects to enhance label artwork and increase shelf appeal. Today we’re tackling the question: what is die cutting and how does it work?

TYPES OF DIE CUTTERS AND THEIR USES

TRADITIONAL DIE

A traditional die cutter is often used in flexographic printing with large printing presses. The die is made from metal or an alternative material that is durable enough to cut through the label substrate. It is formed into the shape of whatever the label will turn out to be, whether this is round, square, or an alternative shape. Usually, you can measure the cost of your die by the intricacy of the die design. Die cutting is hyper precise, so no matter which shape you choose for your label, the execution of your final product will be exactly what you have dreamt up.

BLADE CUTTER

Another version of the die cutter is the blade cutter. This type of cutter doesn’t require the physical “die” that the traditional version of die cutting requires. Instead, the blade is motorized by a computer to be super precise and cut in any shape or design for the size of the press with which your label is printed. Brought about originally for digital printing, the blade cutter has expanded to have applications in flexographic printing as well, meaning label production for intricately cut flexographic printed labels is easier than ever.

LASER CUTTER

Like the blade cutter, this version of the die cutter doesn’t use the traditional die or even a metal device to cut the substrate of the label. Instead, it uses a laser to cut high-precision designs into the label material. This process is extremely quick and can be used for any type of label shape. The emergence of this laser technology into the digital and flexographic printing industry makes customizing your label design easy and seamless.

FREEFORM™ LABELS

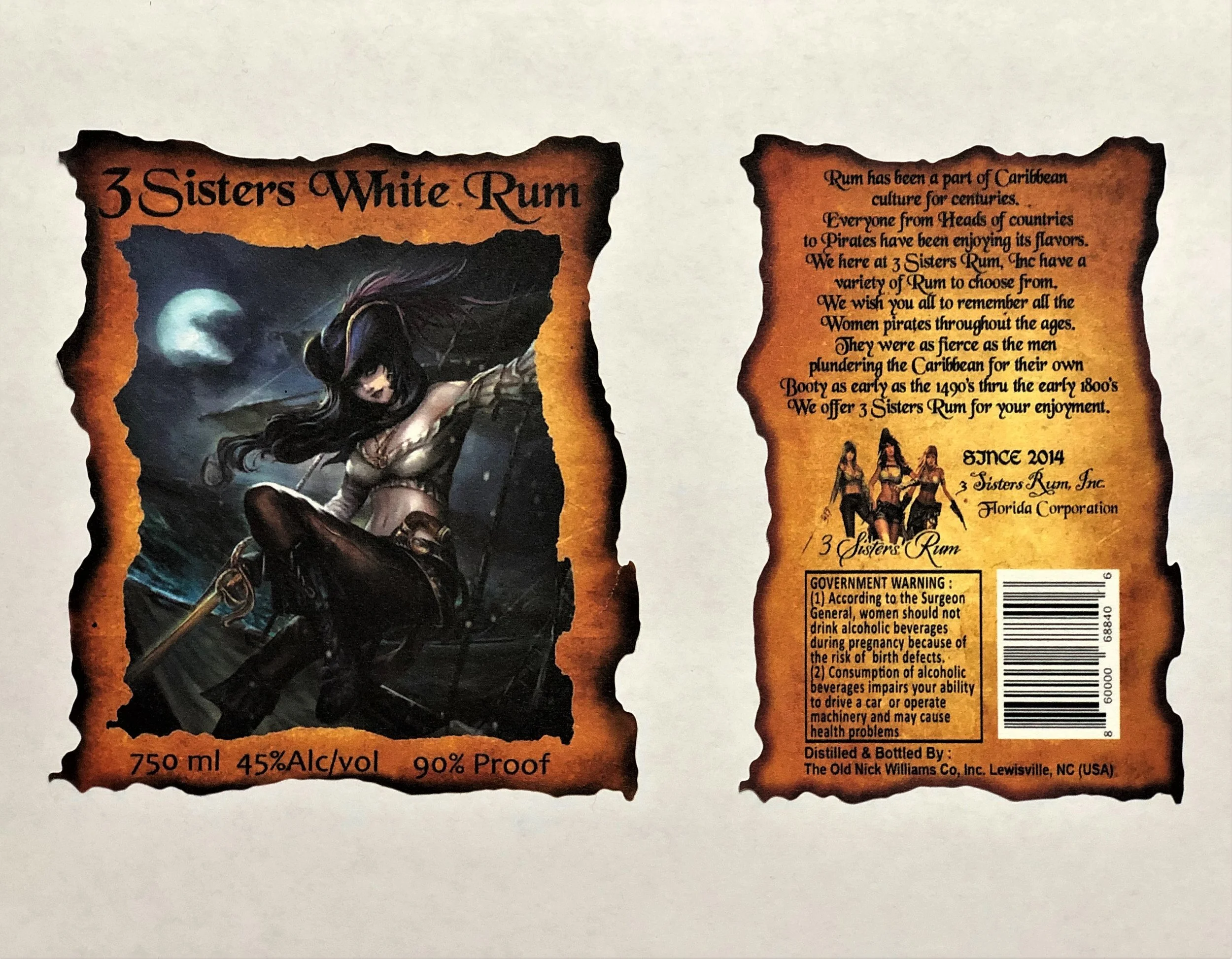

The 3 Sisters White Rum labels from Derksen Co. pictured above were created with freeform™ laser cutting. This process uses a high-powered beam to cut material versus a traditional hard die. The complex exterior shape of the label is made possible by this process and laser-cut technology. Printed on white paper with a permanent adhesive, these labels are ready to be rolled out onto bottles. Combining a matte UV varnish over the top with high-grade artwork makes these labels look sophisticated and fresh.

Now that we’ve answered the question, what is die cutting and how does it work, we invite you to contact us to see how you can incorporate die cutting technologies into your label production. You can contact one of our Derksen Co. team members by calling 920-685-4000 or by dropping us a message using our contact us page.